Transparency in the production process, from clear planning to preventing breakdowns and making immediate adjustments as needed. Production leaders who can quickly and easily understand the process. Production workers who have an overview of their work and their results. Key reasons for change-oriented CoreDux to choose Quinso Manufacturing Execution System (QMES). Read how they switched to a modern shop floor system with real-time reporting in 3 months.

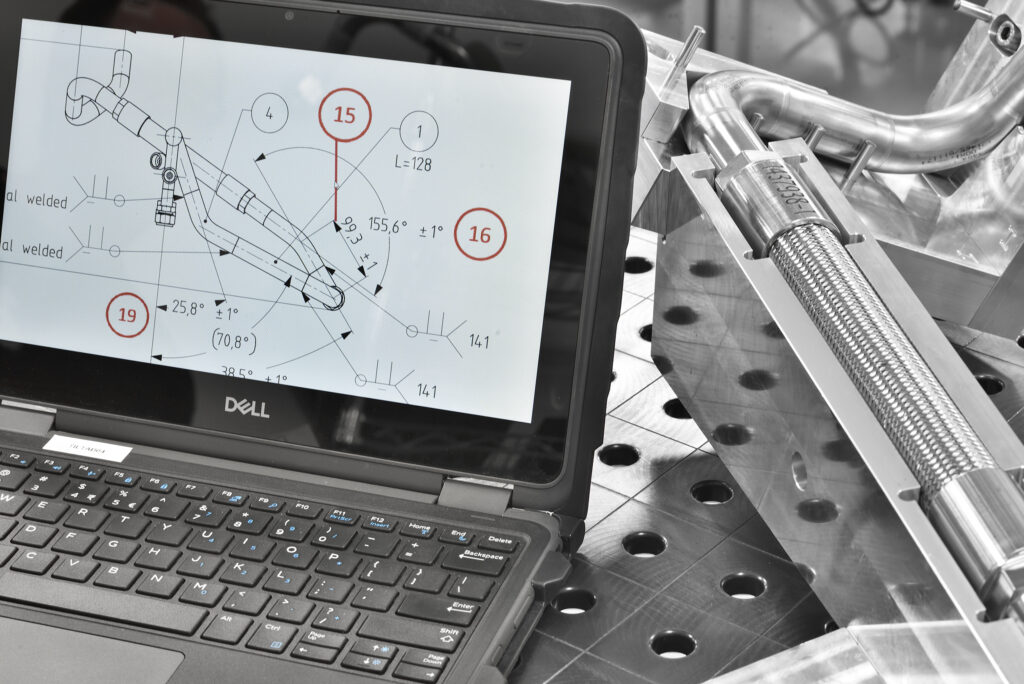

For a rapidly growing organization with ambitions and increasing demand in customization by an international clientele, it is essential to be ahead of that change. CoreDux, designer and manufacturer of layout systems for gas and liquid transport, realizes this better than anyone else.

With locations in the Netherlands, France and Germany, they took a close look at their manufacturing processes. And found that there were gains to be made in better matching the needs of the production team and better serving their customers. To achieve this, they worked with Quinso to ensure a fully transparent production process by implementing Quinso Manufacturing Execution System (QMES).

Transparency in the production process is essential

CoreDux is an all-in-one Original Design Manfacturer (ODM) and System Integrator for gas and liquid transportation systems. Using reliable and flexible solutions, CoreDux makes it possible to connect sophisticated machines, for any application and in any industry. They do this by designing and manufacturing custom durable hoses and arterial systems.

Rens Konings, Manager of Business Process Innovation at CoreDux: “The current MES system was outdated and no longer meshed well with our change-oriented way of working. For that reason, we went looking for a new system. A system that supports the production managers and employees in result-oriented and pleasant work. One that ensures that they maintain an overview and know whether they are achieving the desired results. A system that provides reliable data, so that employees have the opportunity to adjust and they have a clear dashboard to talk to each other and learn from each other’.

Modernized shop floor management system

In the selection process, two main criteria formed the starting point. The solution had to be quick to implement. And it had to be able to meet specific requirements from CoreDux. On Quinso’s advice, CoreDux chose Quinso Manufacturing Execution System (QMES). QMES is an integrated end-to-end shop floor solution based on SAP MII. This solution realizes a direct connection between machines on the shop floor and the operational SAP ERP system. In addition, it enables real-time reporting. QMES was developed by Quinso based on their experience and knowledge specifically for the manufacturing industry.

The fact that QMES creates a good connection between shop and top floor and also fits optimally with the current SAP ECC, CoreDux experienced as additional arguments for choosing this software.

Implementation from partnership

Rens Konings: ‘From the beginning, the contact with Quinso felt equal and familiar. CoreDux and Quinso have a similar hands-on culture and Quinso is noticeably constantly looking for and delivering the best solution for CoreDux.

The implementation of QMES started at the plant in the Netherlands, followed in a later stage by France.

For a quick and smooth implementation, one dedicated team with people from CoreDux and Quinso was formed. A team that focused entirely on implementation. CoreDux focused primarily on change management. On including stakeholders and users in the development and commissioning of the system, and in the change of working as a result of this new system. Quinso created the implementation plan, was responsible for supervising the entire process and, of course, the installation and commissioning of the software, including integration to SAP ECC.

Manufacturing Integration and Intelligence

The project began with the installation of SAP Manufacturing Integration and Intelligence (MII). In workshops the specific requirements were determined. What do we have now and what would we want to have in the ideal future situation. Priorities were set through the MoSCoW method. This is a mode of prioritization often used in software engineering. The requirements for the outcome of a project are thus categorized into: Must haves, Should haves, Could haves and Won’t haves.

Based on these requirements and priorities, the development process began. This was done using the SCRUM methodology. Working software was delivered in short sprints that could be tested, evaluated and modified immediately. This reduced the risk that users could not see and try out the result until the end of the project. And that it would not be developed according to their wishes. This method of working also made it possible to have continuous insight into progress.

After implementing all the requirements into the software system, extensive testing was done until the system was working completely stable. Acceptance testing with users completed the testing phase and ISM could go live!

Karin Lokers, Senior SAP Consultant: ‘In a short time a lot of functionalities were delivered that made the system a lot more user-friendly for CoreDux. Quinso’s added value lies mainly in thinking together, from CoreDux’s specific situation, how to maximize the result’.

Want to read more about the factors that made an essential contribution to the realization of this rapid and nearly flawless implementation? Then read this blog we co-wrote with CoreDux about it.

Ready for planned growth in 3 months

With the commissioning of QMES, CoreDux is ready for planned growth, enabling them to continue to successfully meet the needs and requirements of their international customer base in the future. In just 3 months, CoreDux moved to a completely new and modern shop floor management system.

Rens Konings, Manager of Business Process Innovation at CoreDux: ‘This success is mainly due to the mutual trust between CoreDux and Quinso. Together we managed to achieve this beautiful implementation in a short time!’

Also get the most out of your production process

Are you facing a similar challenge to CoreDux? Do you also want to get more out of your production process? Do you want to take out the inefficiencies? And are you exploring which software is best for you? Also taking into account what your production process looks like now and what it means for the organization and people? Read the blog 7 factors for smooth implementation of manufacturing process transparency software. Or review the digital interactive session “Get the most out of your production process. In which Rens Konings talks about the project CoreDux went through with Quinso: “From decision to solution. Want to know more about Integrated Smart Manufacturing? Then check out the QMES page.