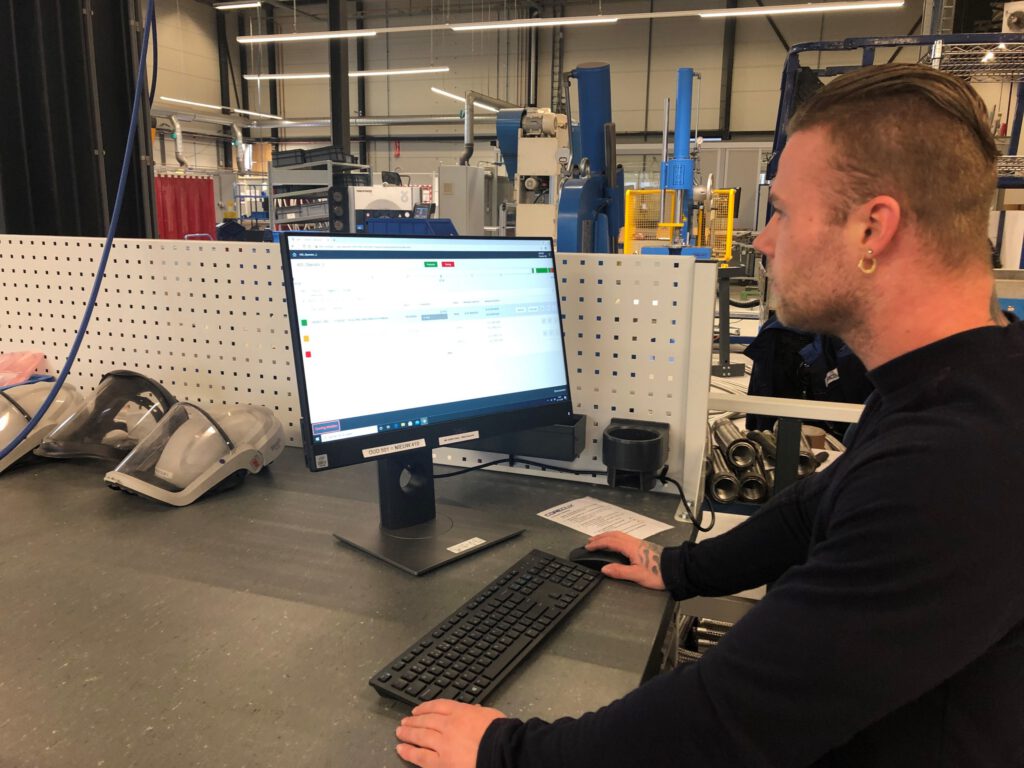

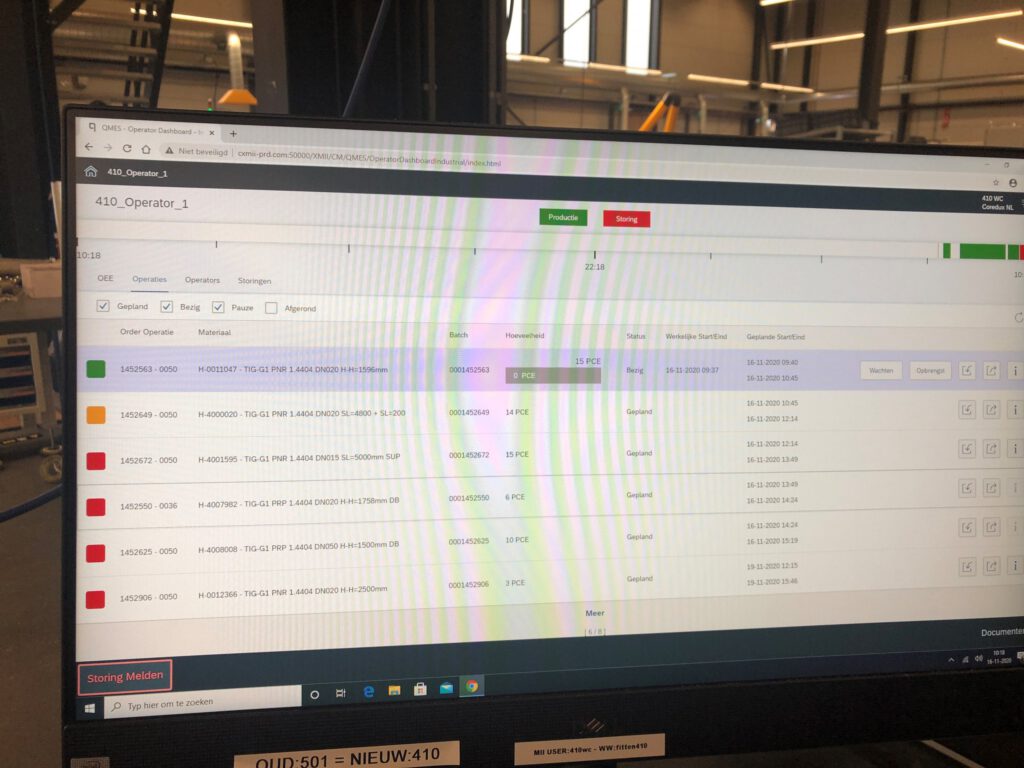

Transparency in the production process, from clear planning to preventing breakdowns and making immediate adjustments as needed. Production leaders who can quickly and easily understand the process. Production workers who have an overview of their work and their results. Important reasons for the change-oriented CoreDux to choose SAP MII (Manufacturing Integration & Intelligence) with Quinso’s in-house developed best practice ISM (Integrated Smart Manufacturing) before the summer on Quinso’s advice. With this, CoreDux is ready for their planned growth and can continue to successfully meet the wants and needs of their international customer base in the future.

CoreDux went to a modernized shop floor management system within 3 months. Workshops with users began in mid-August to clarify requirements. Following the scrum methodology, we then started developing. Prioritize, quickly develop, test and adjust. And keep repeating that. Until the acceptance test and this week’s go live!

Rens Konings, Manager of Business Process Innovation at CoreDux: ‘This success is mainly due to the mutual trust between CoreDux and Quinso. Together we went for an implementation in this short time and together we succeeded!’

Proud of the CoreDux team: Rens Koning, Karin Lokers, Frank van Zwol, Kevin Kolen, Kevin van der Wouw, Lex van Dillen, Werner van Uden. And from Quinso: Wouter Vervoort, Jurgen de Jong, Bram Hendriks and Dick Lemmens.