Research by SAP shows that many Dutch companies are dissatisfied with their supply chains. The reason is that they often deal with complex supply chains involving multiple parties. Whether this complexity comes from a variety of suppliers, a variety of raw materials or multiple production locations, data can help discover, analyze and improve processes throughout the supply chain.

To help companies who want to get started with this a step further, Quinso, together with SAP, organized the event “Get a grip on your supply chain with SAP IBP. For one afternoon, our office and the SAP Experience Center served as an incubator for supply chain managers, SAP specialists and industry planners. They gained insight into how to make their supply chain move with (un)foreseen conditions. In this blog, we look back on the event and are happy to share the 5 takeaways from the speakers with you as well.

1. Integrated planning reduces costs and increases customer satisfaction

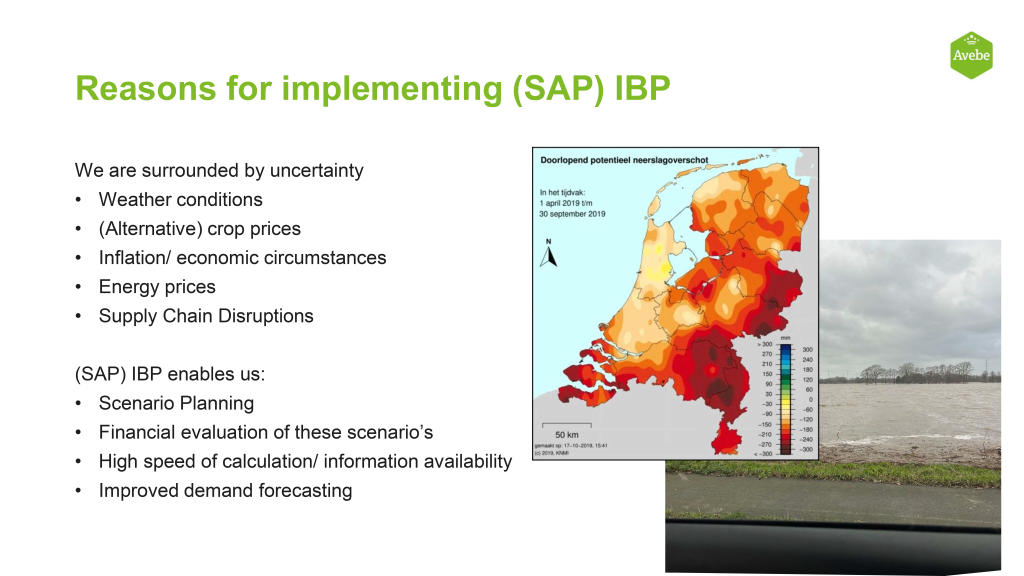

The first takeaway comes from Erik Pricker, Business Planning Manager at Royal Avebe. With more than 1,000 unique finished products spread across 3 production sites in the Netherlands, Sweden and Germany, there is a high degree of planning complexity. Add the enormous dependence on harvest, and therefore weather, to that and you know that flexible scheduling is crucial.

Currently, Avebe has implemented three modules of IBP: SAP IBP for Sales & Operations, IBP Response and Supply and IBP for Demand. After implementing SAP IBP, Avebe saw a significant improvement in their supply chain efficiency. “Demand forecasts became more accurate and inventory levels were optimized. This also made production planning more insightful and efficient. These improvements led not only to cost savings but also to higher customer satisfaction and reliable deliveries,” Pricker says.

2. Make the system work for you

After the real-life story from Royal Avebe, we will head to the SAP Experience Center to dive deeper into the capabilities of SAP IBP. Fabiënne van der Wegen, IBP Solution Specialist at SAP, lets us discover IBP in an interactive way. As a result of all the disruptions in the market, such as a pandemic, blockade in the Suez Canal and resource shortages, we look for a way to make more money quickly: we are going to rob a bank! Every heist hinges on perfect planning, but how do you get it done?

Imagine, you want to grow your organization by 10%, or in the case of the Perfect Heist by €15 million euros. By entering this goal into SAP IBP, scenario planning allows you to see if and how it is achievable. You see what subcontractors are at your disposal, what the alternatives are and what your margin is. In the unlikely event that a resource or subcontractor is not available, the alternatives allow you to still achieve your goal.

3. Be prepared for unexpected events with the right strategy

After the robbery, Fabiënne continues her story. Good supply chain management ensures that your organization can respond quickly to (operational) disruptions and that you have a well thought out and rapidly deployable contingency plan. That you can move with it by predicting disruptions or even preventing them.

Unfortunately, however, it is impossible to see all the changes in the world coming. Therefore, it is very important for your organization to have a strategy that allows your organization to deal with unexpected events to the maximum extent possible. A strategy where all processes are ready at the moment something goes wrong. This strategy has four main components:

- Flexibility

Proactively and profitably sense and respond to market dynamics

- Productivity

Deliver high-quality mass-produced or made-to-order products faster

- Connectivity

Confidential, collaborative relationships with trading partners

- Sustainability

Actively manage environmental and social impact

4. Digital Supply Chain Twin: simulate scenarios and make the right decision

Wouter van Heijst, Director of SAP Business Networks and Direct Procurement Solutions at SAP, then takes us through a presentation on the Digital Supply Chain Twin (DSCT). In short, a Digital Twin is a digital replica of a physical object on all components.

A Digital Supply Chain Twin uses real-time data, artificial intelligence (AI) and machine learning to create a virtual replica of the physical supply chain. Through this digital version, companies are able to simulate scenarios, identify problems early and make smart decisions. A digital supply chain can only function efficiently and cost-effectively with high-quality, accurate and complete data.

But how do you get this data? By betting on SAP software. In doing so, you create a unique position for your organization. In fact, this software ensures that you can populate your Digital Supply Chain Twin with the correct and complete data. You can link the system with Business Networks, Google Analytics and EverStream Analytics, among others. So you can always see the capacity of your suppliers and co-producers and your logistical situation. You are also constantly aware of what potential threats are within your supply chain.

A Digital Twin lets your organization better respond to change and challenges, as you develop a supply chain with more resilience.

5. The opportunities of a sustainable supply chain for efficiency

In the final session, Juriaan Mulder, Business Development Lead for Digital Supply Chain & Sustainability, talks about the opportunities of a sustainable supply chain. The ways you can make your supply chain more efficient are numerous. However, there is no magic solution that drastically changes everything overnight. Therefore, it is good to realize that even smaller tasks that yield marginal profits are rewarding. From a sustainability perspective, you can think about: Does smaller packaging mean more units per shipment? Can smarter ordering mean fewer shipments overall? A 1% increase in efficiency may not seem like much, but if you repeat this 20 times, it suddenly leads to significant improvements throughout your organization. After all, in theory, you are then at least 20% more efficient.

Sustainability in the supply chain is only achievable if you start thinking from one system. The software SAP IBP S&OP (Sales and Operations Planning) the ideal platform to implement sustainable processes throughout the organization.

How do you get a better grip on your supply chain?

Back to the afternoon’s theme. How do you get a better grip on your supply chain? The speakers at the event each answered this from their own perspective. They shared insights, new developments and opportunities. And allowed SAP to experience IBP in practice. Participants were inspired by the sessions and each other. They took the first step in getting a better grip. Is that what you want? Then contact Annemarie deJong directly or fill out the contact form below. Drawing from her experience as a planner and her knowledge of SAP IBP, she is happy to spar with you about the possibilities of getting a better grip on your supply chain.

More inspiration and information? Then check out this page: ‘Get a grip on your supply chain’.