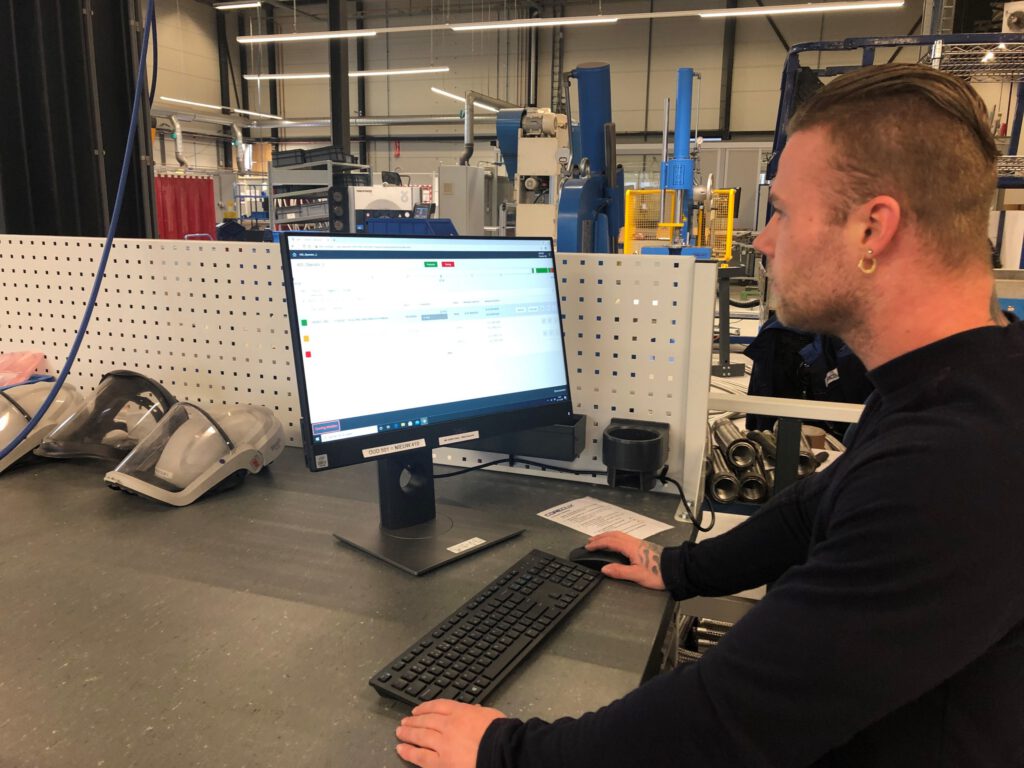

Transparency in the production process, from clear planning to preventing breakdowns and making immediate adjustments as needed. Production leaders who can quickly and easily understand the process. Production workers who have an overview of their work and their results. Important reasons for the change-oriented CoreDux to choose Integrated Smart Manufacturing (ISM) before the summer on the advice of Quinso. A software solution developed by Quinso specifically for the manufacturing industry. In just 3 months, this moved CoreDux to a modernized shop floor management system. Now CoreDux is ready for planned growth and can continue to successfully meet the wants and needs of their international customer base in the future.

Curious about the factors that made an essential contribution to the realization of this quick and nearly flawless implementation? In this blog, Rens Konings and Karin Lokers of CoreDux and Wouter Vervoort of Quinso, share their experience in the form of 7 success factors.

1. Support

First and foremost is support. Our advice: ensure support within all levels of the organization. Board, management and users. Within CoreDux, every layer was convinced that the new software would add great value. An implementation such as ISM, as well as similar software, requires a lot from your organization and your people. If you pull together, you will succeed.

2. Focus

Form one dedicated team with people from your own organization as well as the implementation partner. People from within the organization must be given sufficient time to participate in the implementation. Minimally distracted by day-to-day business, and able to focus fully on the project.

Within CoreDux, there was a dedicated team. So the initial situation was ideal. Practice, however, proved more recalcitrant than we thought beforehand. It remains difficult to focus on the future while the current process also requires attention. Had there been more focus on the new situation, some of the questions and disruptions after the go live could have been avoided.

3. Clear steps in the implementation process

- A third success factor for smooth implementation was a clear approach with concrete steps to follow. Quinso created the plan and was responsible for guidance. Implementation followed these steps:

- The project started with the installation of SAP Manufacturing Integration and Intelligence (MII) with SAP Analytics Cloud (SAC).

- Workshops then determined the specific requirements, requirements. What do we have now and what would we want to have in the ideal future situation.

- Priorities were set through the MoSCoW method.

This is a mode of prioritization often used in software engineering. The requirements for the outcome of a project are thus categorized into: Must haves, Should haves, Could haves and Won’t haves. Learn more about this methodology here. - Based on the requirements and priorities, we began to develop. This was done through the SCRUM method. Working software was delivered in short sprints that could be tested, evaluated and modified immediately. This limited the risk that users can only see and try out the result at the end of the project and it is not developed according to their needs. Another advantage was that there was continuous insight into progress.

- After implementing all the requirements into the software system, extensive testing was done until the system was working completely stable. Acceptance testing with users completed the testing phase and ISM was able to LIVE!

4. Know what you want

Knowing what you want from the beginning ensures that you make the right choices together. Spend enough time on your software requirements. This starts as early as getting to the bottom of the software demo. See what the options are and to what extent they fit the current and, if possible, even already the desired situation. The experience is that almost anything is possible. ISM can be built very flexibly. A lot of customization is also possible in reporting, so CoreDux has taken full advantage of these opportunities.

When you have your requirements clear, you can also make the right choices about what your priorities are and where you want to make concessions.

5. Master data in order

A very obvious one, but certainly no less important. “Rubbish in is rubbish out,” so make sure you have your master data in order before you enter it into the new system. CoreDux started updating the master data even before the start of the implementation process so that when they transitioned to the new system, they had the correct data available immediately.

6. Trust in each other

Perhaps the single most important condition for success: trust in each other. Trust between the organization and the implementation partner. The success of this implementation is largely due to the mutual trust between CoreDux and Quinso. Together we had the same goal, went for an implementation and go live in this short time and together we succeeded.

7. Take your time

From CoreDux, we are happy to have made it in 3 months with Quinso’s guidance and would do it again tomorrow. However, if you can’t answer the aforementioned points positively, avoid disappointment and especially don’t try to do it in 3 months. Take the time that suits your organization and the pace the organization can handle.

Also get the most out of your production process

Over the past 2 years, Quinso has also achieved smooth implementation of the Integrated Smart Manufacturing solution within 3 months at other customers such as Supertape, midocean and Oerlikon.

Are you facing a similar challenge as these organizations? Do you also want to get more out of your production process? Want to take out the inefficiencies and are you exploring which software is best for you? Also taking into account what your production process looks like now and what it means for the organization and people? During the interactive digital session we organized about this on Wednesday, Feb. 10, organizations that have already gone through this process as well as experts from implementation and technology addressed this. Watch the session back here.

Or are you convinced and have a concrete interest in ISM? Then watch the film that is about ISM here. ISM is an SAP Qualified Partner Package solution developed by Quinso specifically for the manufacturing industry. For a fixed amount per month per user and an implementation time of 14-16 weeks, you are already using this integrated end-to-end shop floor solution based on SAP MII. This solution realizes a direct connection between machines on the shop floor and your operational SAP ERP system. Embedded SAP Analytics Cloud (SAC) enables real-time reporting.

Want to know what ISM can do specifically for your organization. If so, contact Wouter directly at 0623731994 or wouter.vervoort@quinso.com. He would be happy to tell you more about it.

Karin Lokers, Senior SAP Consultant at CoreDux.

Karin is a specialist in shopfloor control and MES integration. And also of product cost controlling, quality management, EH&S, warehouse management and production planning. Karin has extensive experience in improving logistics processes as well as adapting SAP systems.

Rens Konings, Manager of Business Process Innovation at CoreDux

Rens has 13 years of all-round business process experience in the retail and manufacturing industries. Thus, he has accumulated extensive knowledge of all aspects of business management and of ERP systems and processes.

Wouter Vervoort, Senior SAP Consultant at Quinso

Wouter has a strong focus on business improvement. His strength lies in coordinating (change) processes, taking into account planning, details, efficiency, cost control and providing a structural solution.